What Is Roof Flashing? DIY Home Improvement

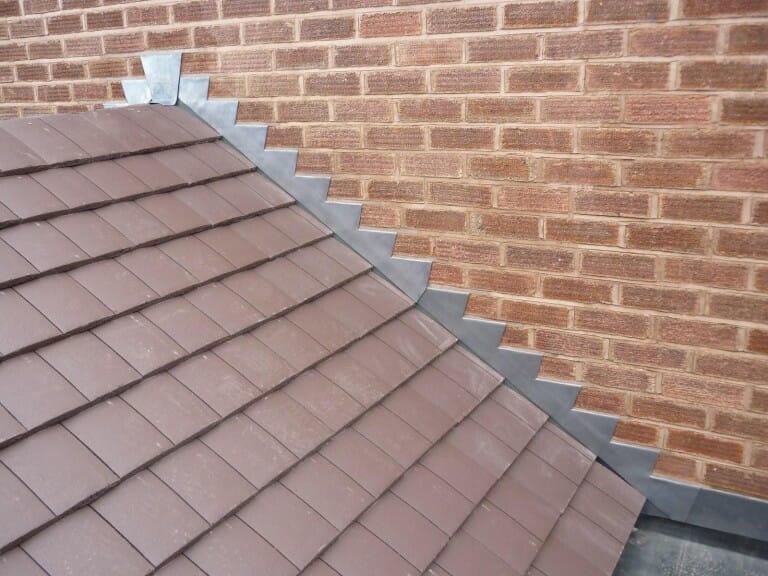

Roof planes that butt up against vertical walls at the end of each new shingle course need to be protected by installing metal step flashing. Metal step flashing pieces are rectangular, approximately 10 inches long and at least 2 inches wider than the face of the shingle being used. For instance, when using metal flashing pieces with IKO.

Custom Made Flashing, Custom Metal Roof Flashing

Roof flashing helps to provide a seal wherever there is a roof joint or penetration (like a chimney or vent), where there is an intersection of two roof surfaces, or where the roof meets an exterior wall.. These days, most roof flashing is made of metal, including galvanized steel, copper, zinc, aluminum, and stainless steel..

Metal Roof Flashing to fit 165267mm Pacific Air

Roof flashing is a thin strip of sheet metal or plastic installed around the edges of roof features such as chimneys, vents, and flue pipes. Roof flashing redirects water away from various other parts of the roof: Roof valleys: Valley flashing is used at the low points of a roof where two slopes join. Roof protrusions: Windows, skylights.

Pin on Roof

4.5. (4) Oatey® Universal Master Flash® Roof Flashings Oatey® Universal Master Flash® Roof Flashings are engineered for metal roof applications at any pitch and accommodate a broad range of pipe diameters. Made of weather-resistant EPDM rubber, these flashings feature marked dimensions for convenient on-site customization.

Endwall Flashing Installation On A Metal Roof. EASY Installation Video Wall Flashing On Metal

Drip edge metal, valley flashing, dormer, chimney, and kick-out flashing shed water away from the connections between roofs, walls, chimneys, and other building assemblies. This collection of 18 articles, animations, and videos identifies the critical roof flashing areas, illustrates durable roof flashing details, and shows how to flash roofs.

Roofing and Flashing Tips Home Exterior Projects Painting, Curb Appeal, Siding & More DIY

Roof flashing is a thin metal material installed to direct water away from areas where your shingles butt up against something (walls, chimneys, valleys, etc.). It's one of the most crucial roofing components that every roof must have to avoid leaks in problem areas. Roof Flashing - Roofing Components Explained to Homeowners Episode 7. Watch on.

Roof Flashing Inspection Gallery InterNACHI®

2. Prepare the Area. Clean the surface where the flashing will be installed, removing any debris, dirt, or old sealant. Ensure the area is dry and free from moisture to promote adhesion. 3. Cut the Flashing. Measure and cut the flashing to the appropriate size using tin snips or metal shears.

HOW TO INSTALL METAL ROOFING?

Step 3: The Installation Process. Here are the steps for installing metal roof flashing. Begin by securing the base flashing, creating a stable foundation. Add step flashing around walls and valley flashing along intersections. Each layer contributes to a seamless flow of water, creating a waterproof roofing system.

Metal Roof Flashing YouTube

Roof Materials Expenses Associated with Flashing Installations and Repairs. The national average cost to hire a roofer to replace the flashing, shingles, and to seal a leak in a small area of the roof is between $300 and $1,100. Larger roof fixes can cost between $1,100 and $1,500+. New Shingle Roof.

Roof Valley Flashing GEIT Metal Roof Accessories Factory

Flashing is a thin, corrosion-resistant sheet metal bent into shape to fit into a joint. Roof flashing helps direct water away from vulnerable areas. It's generally made of galvanized steel.

Metal Roof Metal Roof Flashing

Step 1: Inspect the Roof. The first step is to inspect your existing roof. If it has just a single layer of asphalt shingles, it's a good candidate for a new layer of metal roofing.

Example Residence “B”

To install flashing on metal roofs, start by installing the sidewall trim. Then, cut and finish the end wall flashing, ensuring it aligns perfectly with the sidewall trim. Proceed with the foam closure installation, overlapping the end wall trim. Finally, fasten the end wall flashing for a secure and water-tight seal.

Pin on Gabled end

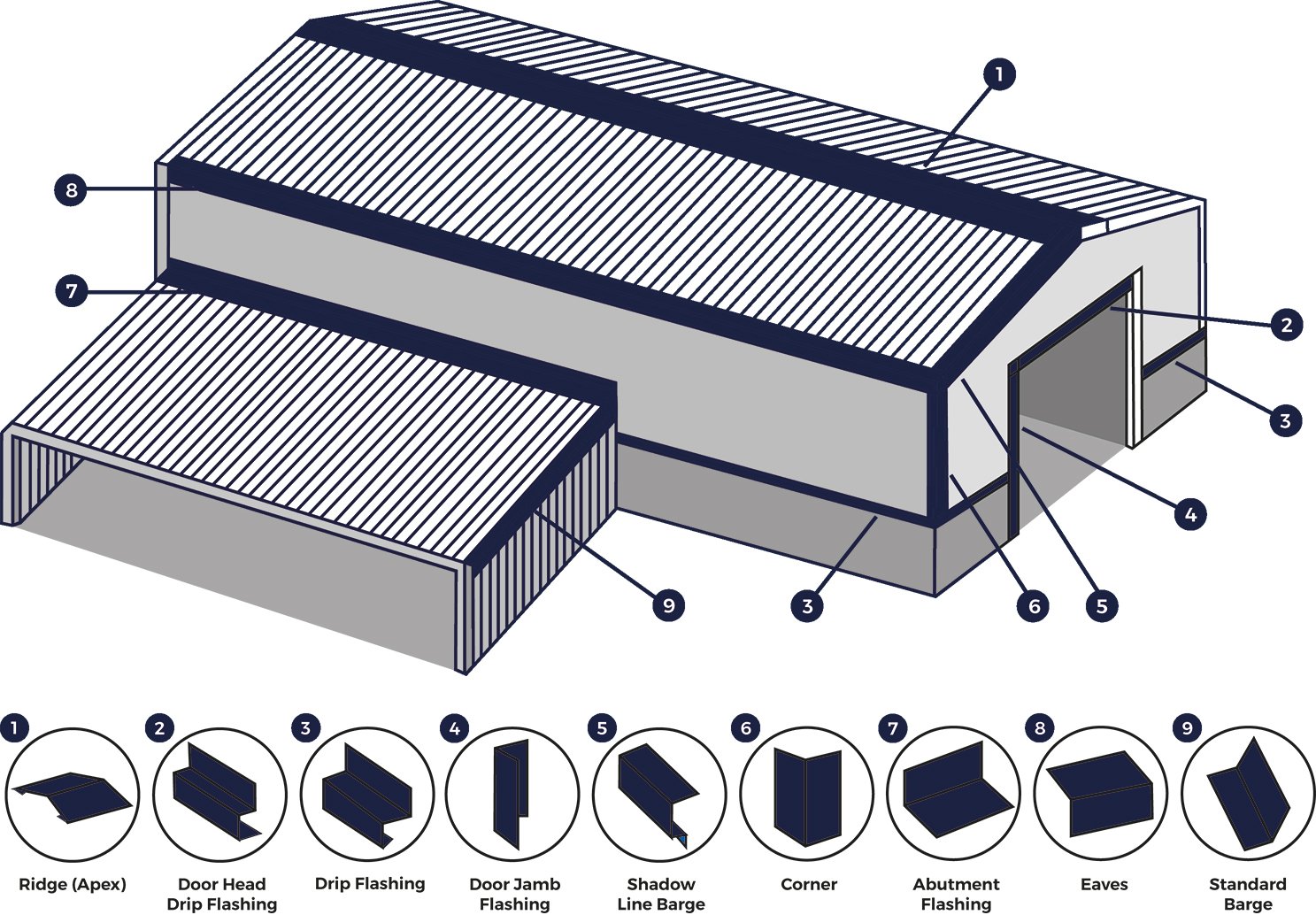

Metal roofing trim is available for each metal panel that we manufacture. Use our trim and metal flashing center to find the metal roof trim option that's best for your roof or wall panel. Dimensions, details, and installation videos for each trim piece including gable, ridge, roof edge, fascia, valley flashing, eave trim, transition flashing.

Pin on Metal Roof Flashing

Features: Our roof jacks for roofing's design caters to a diverse range of applications, from roofing to patching, and ventilation ducts to chimneys. An essential addition to every handyman's kit, the roofing pipe flashing boot epitomizes versatility and practicality, making it an integral part of the household or professional toolbox.

Roof Flashing Basics (types of flashing and installation techniques) Sol Vista Roofing

Roof flashing is an essential part of any roofing system, and it's important to understand the different types available. From metal flashings to plastic, rubberized asphalt, copper and lead-coated copper as well as aluminum and steel - there are a variety of options when it comes to roofing flashing types.Each type has its own unique benefits that can help you make an informed decision on.

Metal Flashing Roofing Sheet, Rs 86 /kilogram Nataraj Roofing Private Limited ID 5370776430

Firstly, thoroughly cleanse the metal roof surface where the flashing will be added. Remember, water and debris can impede correct installation, affecting the final result. Keep in mind, flashing is a critical component of roofing, especially for metal roofs, as it protects your home from water intrusion. Following a guide can help ensure a.